Plate heat exchanger seal fixing and replacement technology

Plate heat exchangers are an important part of heat exchange technology in process industry equipment. The elastic gasket that seals between the various plate fins is a consumable part and is also an easily aging part under natural conditions. Its service life has an important influence on the service life of the plate heat exchanger. If these seals heat harden and lose their original elasticity, the heat exchanger will not work properly.

1. Sealing of the seal:

In principle, the fixing of the sealing member is divided into two categories: adhesive fixing and non-bonding fixing. The shape of the gasket should be consistent with the shape of the plate heat exchanger seal. It must be pointed out that the adhesive fixing method does not have any effect on the sealing function.

(1) Non-adhesive sealing alignment: placing the sealing ring in place: placing the sealing ring correctly into the sealing groove: in the sealing groove, there is a trough structure with a gradually decreasing cross section, so as to make the sealing ring Correct positioning.

(2) Adhesive seal

Depending on the purpose of the gasket and the quality of the seal, blending sealants and non-harmonic sealants from different manufacturers can be used. Before bonding, a vapor stream should be used to thoroughly remove the adhesive remaining on the bonding surface and the residual gasket. For blended sealant bonding, the residual adhesive and residual gasket on the bonding surface of the plate heat exchanger must be burned off. When bonding in large quantities, the liquid nitrogen tank of the frozen seal should be prepared, and the heating furnace for drying the plate heat exchanger with gasket should be prepared. The heating temperature should be 160 ° C. If conditions permit, the plate should be prepared. The heat exchanger is chemically cleaned to ensure complete removal of the gasket of the bond remaining in the bonded surface of the plate heat exchanger.

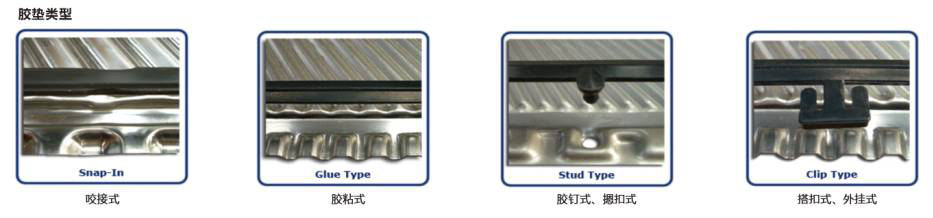

The ice plate heat exchanger gasket is of different types such as snap-in type, adhesive type, snap-on type, and external type, as shown in the following figure;

2. Replacement of seals:

(1) Inspection and testing of recyclability. The wall thickness of the heat exchanger and the pipe is checked in case of rust.

(2) The aging seals are removed, and the acid-alkali cleaning tank is used for chemical cleaning according to different dirt, and the surface of the parts to be cleaned is not corroded by chemical media (such as gasoline).

(3) After the chemical cleaning, the chemical medium remaining on the surface of the plate heat exchanger or the like is thoroughly removed by a high pressure purging device.

(4) Each heat exchanger plate is coated with a fluorescent test agent, and under the irradiation of ultraviolet light, it is checked whether there are fine cracks and corrosion holes, and is re-cleaned. In addition, it is important to check the condition of the seal groove and trim if necessary.

(5) For the adhesive gasket, the residual material will be completely removed, and the re-bonded adhesive will be re-bonded. The recombined heat exchanger sheet will be clamped in the special fixture to cure the adhesive; Heat and heat in the furnace to achieve a good bonding effect. For non-adhesive gaskets, different devices are used to secure the gasket in the heat sink.

(6) The bonding position and bonding quality of each plate type heat sink are inspected, classified according to the installation order, and then the plate type heat sink group is carefully and carefully assembled.

The quality of the sealing gasket of the plate heat exchanger determines the service life of the plate heat exchanger. For a large number of heat exchangers, the plate is generally not damaged, and the gasket is prone to aging and cause leakage, so The quality of the gasket determines the quality and service life of the heat exchanger. The ice-plate heat exchanger uses the high-quality heat exchanger gasket produced by the company as the matching gasket to ensure the long-term service life and operational reliability of the ice-plate heat exchanger.